Modern manufacturing is undergoing a profound transformation, driven by advancements in digital design, automation, and material science.

At the forefront of this evolution is Repmold, a technology and methodology that is redefining how molds, prototypes, and components are created.

Repmold integrates rapid prototyping, precision tooling, and automated workflows to deliver products faster, more efficiently, and with higher quality than traditional methods.

As industries demand faster innovation cycles and greater flexibility, Repmold offers a pathway to a future where manufacturing is smarter, faster, and more sustainable.

Understanding Repmold: Technology and Principles

At its core, Repmold represents a fusion of digital design and advanced molding processes.

Engineers begin by creating detailed digital models of parts or molds using CAD (Computer-Aided Design) software.

These models undergo virtual testing and simulation, allowing potential design flaws to be identified long before physical production begins.

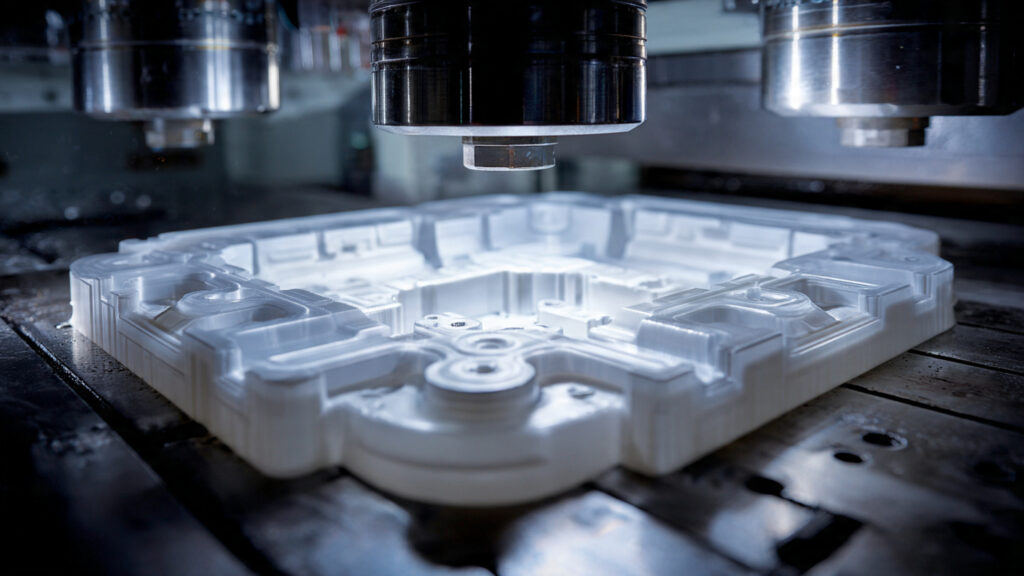

The next step involves rapid prototyping, using tools such as 3D printing or CNC machining to produce highly accurate mock-ups.

This approach reduces trial-and-error cycles, lowers material waste, and ensures that the final molds are both precise and reliable.

By combining digital precision with efficient production, Repmold allows manufacturers to respond to market demands with unprecedented speed.

Key Benefits of Repmold in Modern Manufacturing

Repmold provides several transformative benefits for the manufacturing sector.

First, it accelerates production timelines. Companies can go from initial design to ready-to-use molds in a fraction of the time required by conventional methods.

Second, the methodology is cost-effective. By minimizing wasted materials and labor-intensive manual processes, Repmold helps reduce overall production costs while maintaining quality.

Third, Repmold supports scalability. Small-batch prototypes or high-volume runs can be produced with consistent accuracy, making it ideal for industries from medical devices to automotive components.

Finally, the integration of digital workflows contributes to sustainable manufacturing practices. Material usage is optimized, scrap is minimized, and resources are deployed more efficiently, supporting eco-conscious production goals.

Safety, Quality, and Operational Considerations

While Repmold itself is not a chemical or consumable product, safety and quality remain critical in its implementation.

Operators must follow industrial safety protocols when using automated machinery, CNC tools, or rapid-prototyping systems.

Training, regular equipment maintenance, and adherence to workflow standards are essential to ensure high-quality output and prevent workplace accidents.

Material selection also plays a crucial role; using the correct metals, polymers, or composites ensures the final components meet required strength and durability standards.

When implemented correctly, Repmold allows manufacturers to maintain rigorous quality control while benefiting from automation and digital efficiency.

Industry Applications and User Insights

Repmold has gained significant traction across multiple industries due to its flexibility and precision.

In automotive manufacturing, engineers can test and refine new parts rapidly, reducing the time from concept to market.

In medical device production, Repmold’s high precision ensures that components meet strict regulatory and tolerance requirements, while speeding up prototype development.

Startups and small-batch producers also benefit from Repmold’s adaptability, allowing them to launch products faster and iterate designs without the high costs associated with traditional tooling.

Feedback from users highlights its efficiency and accuracy as major advantages, though some note that upfront investment in training and digital integration is necessary to fully realize its potential.

Repmold vs. Traditional Manufacturing Methods

Traditional molding methods, such as long-lead injection molding, require extensive manual setup, testing, and iteration.

This process is often slow and inflexible, making it challenging to adapt quickly to design changes or market demands.

Repmold bridges the gap between prototyping and full-scale production by combining digital design, rapid prototyping, and precision molding.

The result is a hybrid approach that delivers speed, consistency, and quality while minimizing wasted time and resources.

Manufacturers leveraging Repmold can iterate designs faster, reduce errors, and scale production efficiently, giving them a competitive edge in dynamic markets.

The Future of Manufacturing with Repmold

Repmold represents a revolutionary shift in how manufacturing is approached.

By integrating digital workflows, automation, and precision tooling, it is enabling a new era of smart, responsive, and sustainable production.

As industries continue to demand faster innovation cycles, higher product quality, and environmentally responsible practices, Repmold positions itself as a cornerstone of modern manufacturing.

Companies that adopt this technology are not only improving efficiency and reducing costs but also preparing for a future where flexibility and adaptability are paramount.

Conclusion: Why Repmold Matters

Repmold is more than just a manufacturing tool—it is a transformative methodology shaping the future of industrial production.

Its combination of speed, precision, scalability, and sustainability makes it a critical asset for businesses striving to innovate in competitive markets.

For manufacturers, engineers, and product designers, Repmold offers a pathway to faster, safer, and smarter production, redefining what is possible in modern manufacturing.

As industries embrace digital transformation, Repmold stands at the forefront, ensuring that the next generation of manufacturing is both innovative and resilient.