Introduction

In the ever-evolving landscape of industrial materials and surface protection, ceramic coatings have gained prominence due to their exceptional properties such as high temperature resistance, durability, corrosion resistance, and aesthetic appeal. Among the myriad of ceramic materials available, Sodiceram stands out as a leading innovation, revolutionizing various sectors including aerospace, automotive, electronics, and industrial manufacturing.

This article provides an in-depth exploration of Sodiceram, encompassing its composition, properties, applications, manufacturing processes, advantages, and future prospects.

What is Sodiceram?

Sodiceram is a specialized ceramic material primarily composed of sodium silicate-based compounds, often combined with other oxides and additives to enhance specific properties. Its unique chemical structure confers high thermal stability, chemical resistance, and excellent adhesion to a variety of substrates.

Sodiceram is often developed as a coating or an additive in composite materials, serving as a protective barrier or functional layer in demanding environments.

Composition and Structure

Basic Composition

- Sodium Silicate (Na₂SiO₃): The core component, providing the fundamental silica network.

- Binders and Additives: Elements such as alumina, zirconia, titanium dioxide, or other oxides are incorporated to tailor properties like hardness, thermal expansion, or electrical conductivity.

- Fillers and Reinforcements: Ceramic particles or fibers may be added to improve mechanical strength and durability.

Microstructure

Sodiceram exhibits a vitreous or glass-ceramic microstructure, characterized by a network of silica-based bonds. This structure imparts high thermal stability and resistance to thermal shock. The microstructure can be engineered to optimize properties like porosity, adhesion, and flexibility.

Key Properties of Sodiceram

1. High Thermal Resistance

Sodiceram coatings can withstand temperatures exceeding 1,200°C (2,192°F) without degradation, making them ideal for high-temperature applications.

2. Chemical Resistance

Exceptional resistance to acids, alkalis, solvents, and other corrosive agents ensures longevity and reliability in aggressive environments.

3. Mechanical Strength and Hardness

Sodiceram offers high hardness and wear resistance, reducing erosion and mechanical failure over time.

4. Excellent Adhesion

It adheres strongly to metals, ceramics, plastics, and composite surfaces, facilitating durable protective layers.

5. Thermal Shock Resistance

The material can endure rapid temperature fluctuations without cracking, crucial for applications involving cyclic heating and cooling.

6. Insulating and Conductive Properties

Depending on composition, Sodiceram can be engineered for electrical insulation or conductivity, broadening its application spectrum.

Manufacturing Processes

1. Powder Processing

Sodiceram powders are synthesized via sol-gel methods, spray drying, or calcination. These powders are then processed into pastes, paints, or dry forms.

2. Coating Application

- Spray Coating: Using air or plasma spray techniques for uniform application on large or complex surfaces.

- Brush or Dip Coating: Suitable for smaller components or localized repairs.

- Slip Casting or Casting: For creating thick, monolithic ceramic parts.

3. Curing and Firing

Post-application, the coatings or parts are cured at controlled temperatures to achieve the desired microstructure and properties.

4. Surface Treatments

Additional steps such as polishing, sealing, or laser treatments can be performed to enhance surface finish and performance.

Applications of Sodiceram

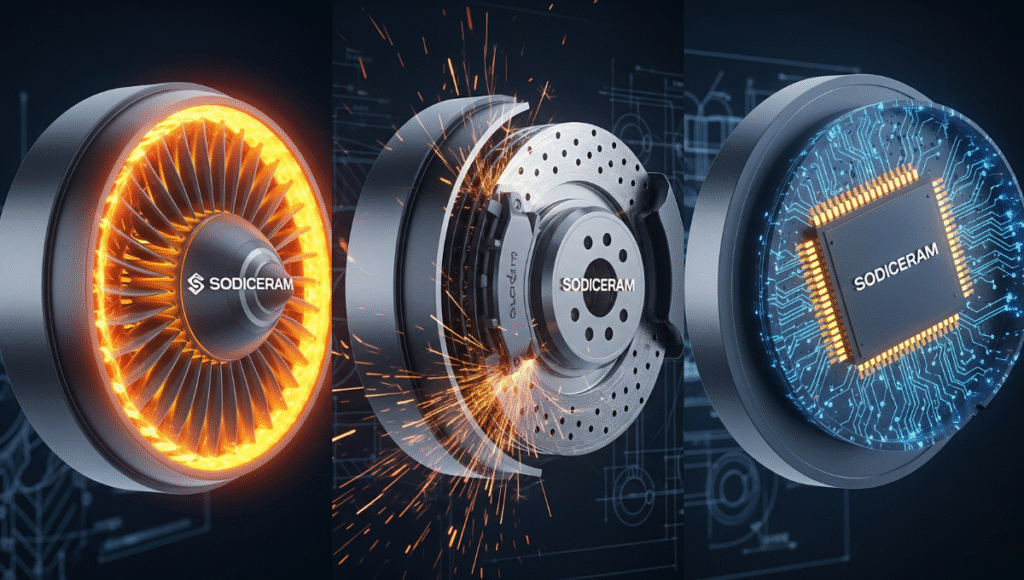

1. Aerospace Industry

- Protective coatings for turbine blades, combustion chambers, and exhaust systems.

- Thermal barrier coatings to insulate components exposed to extreme temperatures.

2. Automotive Sector

- High-performance brake pads and engine components.

- Coatings for exhaust systems to resist corrosion and thermal degradation.

3. Electronics and Semiconductor Manufacturing

- Insulating layers in electronic devices.

- Protective coatings for sensitive components against thermal and chemical stresses.

4. Industrial Equipment

- Linings for furnaces, kilns, and reactors.

- Wear-resistant coatings in mining, cement, and steel industries.

5. Medical Devices

- Biocompatible ceramic coatings for implants and surgical tools.

Advantages of Sodiceram

- Durability: Long-lasting and resistant to wear and corrosion.

- Versatility: Applicable across numerous industries and substrates.

- Cost-Effective: Reduces maintenance and replacement costs due to high longevity.

- Eco-Friendly: Many formulations are environmentally benign and comply with regulatory standards.

- Customizable: Composition can be tailored for specific properties and applications.

Challenges and Limitations

While Sodiceram offers numerous benefits, certain challenges persist:

- Processing Complexity: Achieving uniform coatings and optimal microstructures requires precise control.

- Cost of Production: High-purity raw materials and advanced manufacturing techniques can be expensive.

- Brittleness: Like many ceramics, Sodiceram can be brittle; ongoing research aims to improve toughness.

Future Prospects and Research Directions

The future of Sodiceram is promising, driven by ongoing developments in nanotechnology, additive manufacturing, and composite materials. Current research focuses include:

- Enhanced Toughness: Developing composite formulations to mitigate brittleness.

- Smart Coatings: Integrating sensors or self-healing capabilities into Sodiceram-based coatings.

- Environmental Sustainability: Creating eco-friendly manufacturing processes and recyclable formulations.

- Biomedical Applications: Expanding biocompatibility and bioactive properties for medical use.

Conclusion

Sodiceram stands as a remarkable advancement in the realm of ceramic materials, offering superior thermal stability, chemical resistance, and mechanical strength. Its versatility and customizable nature make it indispensable across high-demand sectors such as aerospace, automotive, electronics, and industrial manufacturing. As research progresses, Sodiceram is poised to unlock new applications and set new standards for high-performance ceramic coatings.

Choosing Sodiceram means opting for a durable, reliable, and innovative solution—one that continues to push the boundaries of what’s possible in surface protection and material engineering.